spaceshot 2024

Mission Overview

Aftershock is USCRPL’s most ambitious project yet. The mission of Aftershock is become the highest and fastest travelling student-built rocket of all-time. Aftershock is the successor to Traveler IV (USCRPL’s First Successful Spaceshot), as such every aspect of the rocket has redesigned and improved in order to go higher and faster. Aiming to shatter world-records in the fields of both amateur and student rocketry.

Highest altitude achieved (Student + AMateur Rocketry)

Current student rocketry record is held by USCRPL when in 2019 ‘Traveler IV’ reached 339,800 ft (103.6 km). Current amateur rocketry record is held when in 2014 ‘GoFast’ reached 385,800 ft (117.6 km). Aftershock aims to shatter this record by reaching 490,000 ft (149.0 km), which is nearly at the FAA limit for amateur rocketry at 492,000 ft (150.0 km).

Fastest Velocity achieved (student + Amateur Rocketry)

Current student rocketry record is held by USCRPL when in 2019 ‘Traveler IV’ reached 4,966 ft/s (1,513 m/s). Current amateur rocketry record is held when in 2014 ‘GoFast’ reached 5,250 ft/s (1,600 m/s). Aftershock is simulated to break both records by achieving 5,600 ft/s (1,700 m/s).

Technical Details

| Apogee | 490,000 ft (149,000 m) |

| Max Velocity | 5,600 ft/s (1,700 m/s) |

| Motor Designation | GEM8-R4000 |

| Max Thrust | 4,220 lbf (18,771 N) |

| Burn Time | 16.3 s |

| Total Impulse | 51,529 lbf-s (229,212 N-s) | Total Vehicle Mass | 322 lbm (146 kg) | Dry Mass | 123 lbm (56 kg) |

| Propellant Mass | 199 lbm (90 kg) |

*All Values are in Vacuum Performance, **Apogee and Max Velocity Values are Simulated

Structures

Case |

| Built entirely in-house, this structure serves both as the combustion pressure vessel and the airframe, making Aftershock a minimum diameter rocket. Featuring USCRPL’s signature filament-wound carbon epoxy design with co-bonded insulation, this will be the longest case the club has ever flown. A body length of over 110 inches gives space for the organization's biggest motor, making this the largest-ever amateur carbon-case motor to fly with solid propellant. Finally, in response to heavy erosion seen on Traveler IV’s trailblazing flight, Aftershock will employ a thermal-protection system (TPS) never before used at this scale. |

Nosecone |

| Another one of USCRPL’s crown developments, an ablative cork TPS on the conical nosecone ensures the protection of avionics components from heat and structural failure. In addition to the case, the nosecone will bring the total length of the vehicle to 13 feet. By bonding together fiberglass, cork, and metal in all the right ways, this structure withstands immense heat to give way to the vehicle’s recovery system at apogee. |

Nozzle |

| The nozzle is comprised of heat-resistant carbon phenolic prepreg and a graphite throat. These materials were selected to be as light as possible while maintaining their geometries over the course of the firing. Excessive erosion ruins the nozzle efficiency, but both graphite and carbon phenolic will resist the intense forces of the supersonic gases propelling the rocket. Bonded together with state-of-the-art metal retention components, this will be the club’s lightest nozzle to date. |

Fins |

| Similar to the case, the fins on Traveler IV saw immense erosion. Aftershock will utilize USCRPL’s standard four carbon fiber fins, pressed to a precise thickness and held on with carbon fiber that reaches from the edge of each fin to the next. However, this vehicle will feature cutting-edge metal leading edges on the fins to ensure that their critical aerodynamic profile is not compromised over the course of flight. Tested on a previous vehicle, this will be the first time this technology is used on a spaceshot and will highly improve the reliability with which Aftershock reaches its designed altitude. |

PRopulsion

Propellant |

| USCRPL mixes and casts a custom ammonium perchlorate composite propellant (APCP) to propel its rockets. Using a formula developed by students in the club, each propellant grain is made by USCRPL starting from raw chemicals, setting the club apart from many other collegiate rocketry teams. With nearly 200 pounds of propellant, Aftershock's motor, comprised mainly of BATES-type propellant grains, will be the largest built by USCRPL. |

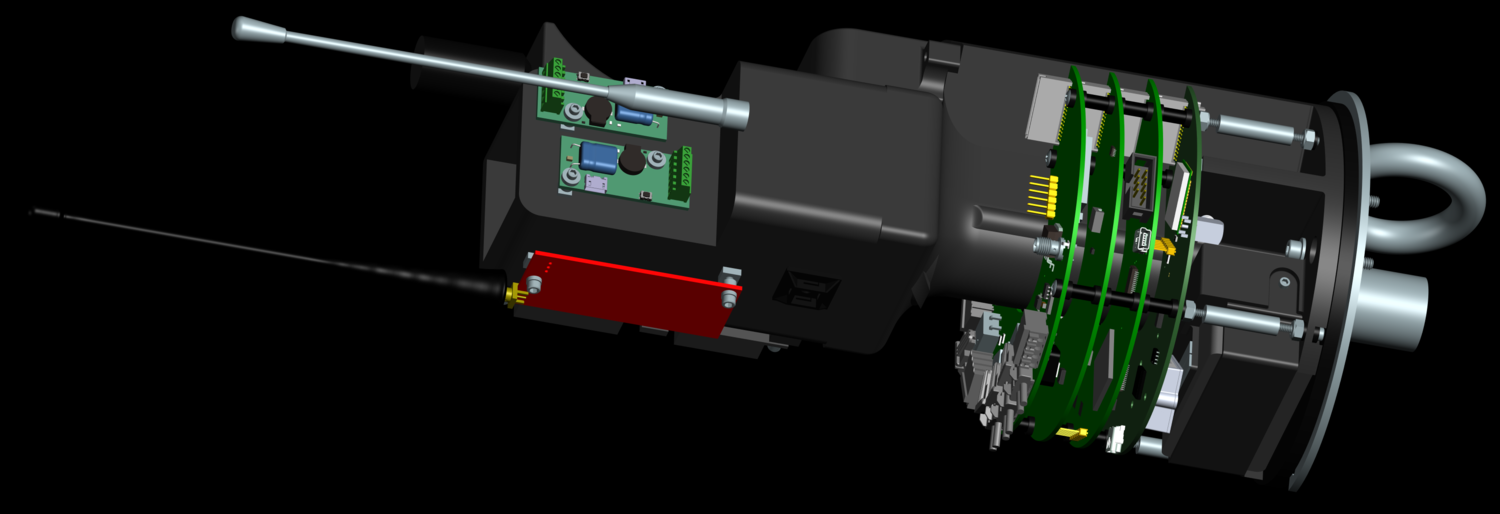

Avionics

Our flight computer HAMSTER consists of 5 PCBs we've designed and laid up in house.

Power Board |

| The first is our power board which delegates power throughout our system and bypasses the protective circuitry of our battery packs to allow HAMSTER to run significantly longer. |

Connector Board |

| The second is our connector board which interfaces with all of our 3rd party commercial off the shelf (COTS) components! |

Rangefinder Transponder |

| The third is our Rangefinder transponder. It performs radio-based distance measurements between multiple points on the ground with the rocket as it ascents, allowing us to gather critical altitude information where systems like GPSs would lock out due to COCOM (read this paper for the original thesis paper: (https://engrxiv.org/preprint/view/1655/4292). |

Sensor Board |

| Fourth on our stack is our sensor board which, as the name implies, gathers data on sensors (acceleration, temperature, barometric, and GPS). It also executes our flight software. |

Integrator Board |

| Finally we have our integrator board that performs sensor fusion on magnetometer, gyroscopic, and acceleration data. It takes this information in the inertial frame and uses it for live integration to determine burnout velocity among other parameters! |

Recovery

Single-deployment System |

| A single deployment recovery system will be used to ensure safe landing at roughly 65 ft/sec . The nosecone is ejected at apogee from a punctured CO2 canister. The Nosecone and airframe separation will passively deploy the parachute, and inflation will begin once it enters the atmosphere. In addition to a robust parachute, a 360 camera and GPS will also be connected to the tether for post flight footage and recovery operations. |